We are focused on research and development for innovative healthcare solutions from natural sources. It follows stringent and universally accepted medical norms for standardization, validation and product development, ensuring world class quality and consistent performance. We have top class laboratories in Pharmacognosy & Phytochemical, Microbiology, Instrumentation, Preclinical & toxicological, Formulation & Development. Our immediate focus is to develop a complete range of nutraceuticals and dietary supplements that will support the deficiency of the victims of life style diseases. We also have ambition to create truly premium class skin and body friendly range of cosmetics.

Our strength lies in our people. Our core team consists of highly trained scientists and experts, adequately qualified in diversified field like Ayurvedic Pharmacy, Microbiology, Chemistry, Botany, Phytochemistry etc. which made us possible to set new standards of excellence in this field. The effort of team is proven with number of awards and certification received till date.

The R&D Unit has evolved stringent methods for analyzing and testing of raw materials and end products. Various new methods used to developed standardization of herbs and products with in line of pharmacopoeial and ICH guidelines. A dedicated team of researchers and quality experts are engaged in research and development of new formulations and standardization of drugs.

R&D division of the company focuses on various research areas viz. Herbal and Ayurvedic Pharmaceutical, Phytochemical, Cosmeceutical, Analytical, Clinical, Nutraceutical Research and Development. For us research is the core part for development of products and treatments, and we are rigorously involved in preclinical as well as clinical studies in our well equipped with the most modern research facilities.

Pharmacognosy and Phytochemical Laboratory

Research in Ayurveda is important because it leads new types of therapeutic moiety, increased understanding of the pharmacological, ecological and biochemical roles of molecules produced by nature; new methods for the analysis of drugs and herbal formulations. The laboratory provides all the facilities for identification, standardization and analysis of raw materials and finished products by following Indian Pharmacopoeia, United state pharmacopoeia and Ayurvedic pharmacopoeia.

Microbiology Laboratory

The Department of Microbiology is focused on research protocol for microbiological analysis including microbial pathogens like Escherichia coli, Staphylococcus aureus Salmonella sp, Pseudomonas aeruginosa etc. Here we conduct In-vitro bioassay-guided fractionation as a part of new formulation development and total bio-burden of herbal raw materials and finish goods to ensure safety and stability of our products.

Instrumentation Laboratory

The laboratory includes all the facilities for standardization and identification of phyto-constitutents, analysis of raw material and finished products, stability of finished products and many more. The Laboratory provides esteemed guidelines regarding natural sources of drugs and phytochemical screening through various instruments like spectrophotometer, HPLC, GC, etc. Our facility is capable to conduct heavy metal analysis, pesticides analysis, stability studies etc. We had development the authentic analytical methods which can reliably profile the phytochemical composition, including quantitative analysis and testing of marker/bioactive compounds and other major constituents.

Formulation and Development Laboratory

Our pharmaceutical development team is experienced in the pre-formulation and formulation. The laboratory is well equipped with various modern equipment and technologies required for conducting high quality research activities. Pharmaceutical formulation capabilities include:

Capsules Tablets Gels Creams Ointments Suspensions Suppositories Granules

Preclinical and toxicological study Laboratory

We had CPCSEA approved animal house facility. Here, we have conforming the safety and bio-efficacy of our products to avoid the possible side effects, adverse reactions at the maximum tolerable dosages. To do so, the laboratory is very well equipped and specially designed to carry out various in-vivo and in-vitro experiments on isolated organs and tissues. Bioassays, Dose Response Curve (DRC) studies and toxicological studies of formulations by various animal models like analgesics, anti-inflammatory, antidiabetic, antiasthmatic, antiulcer, antiarthritic, urolithiatic, wound healing, etc are carried out.

Clinical trials department

Our Clinical Trial team comprises graduates and post-graduates of high academic excellence in the field of Medical, Pharmacy and Allied Sciences. The team is responsible for the clinical development of phyto-pharmaceuticals and to provide inputs for various drug discovery projects. The department is responsible for the conceptualization, design and to conduct trials. It is accountable to ethics committees and responsible for regulatory body clearance, data analysis, evaluation and reporting of clinical trials.

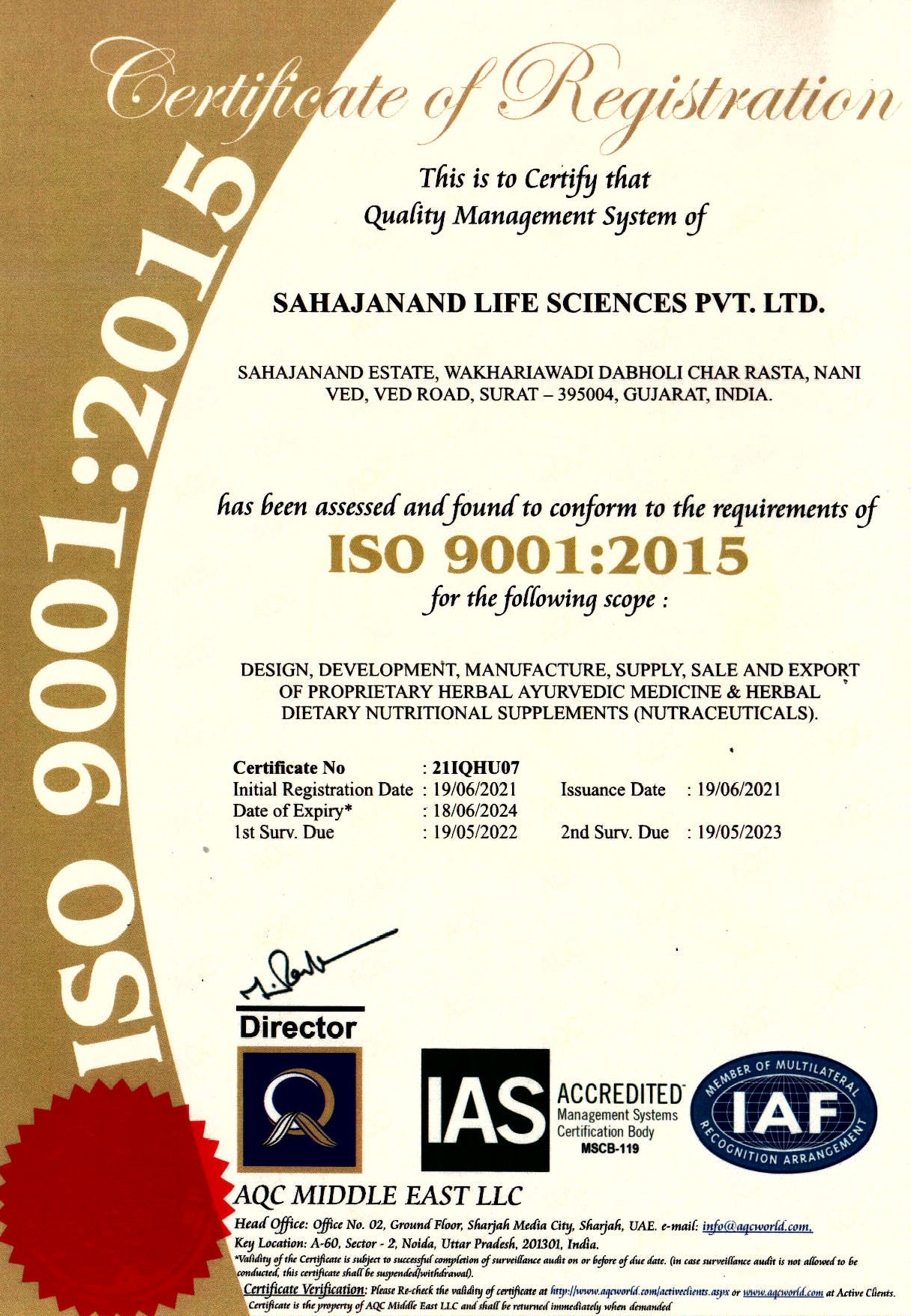

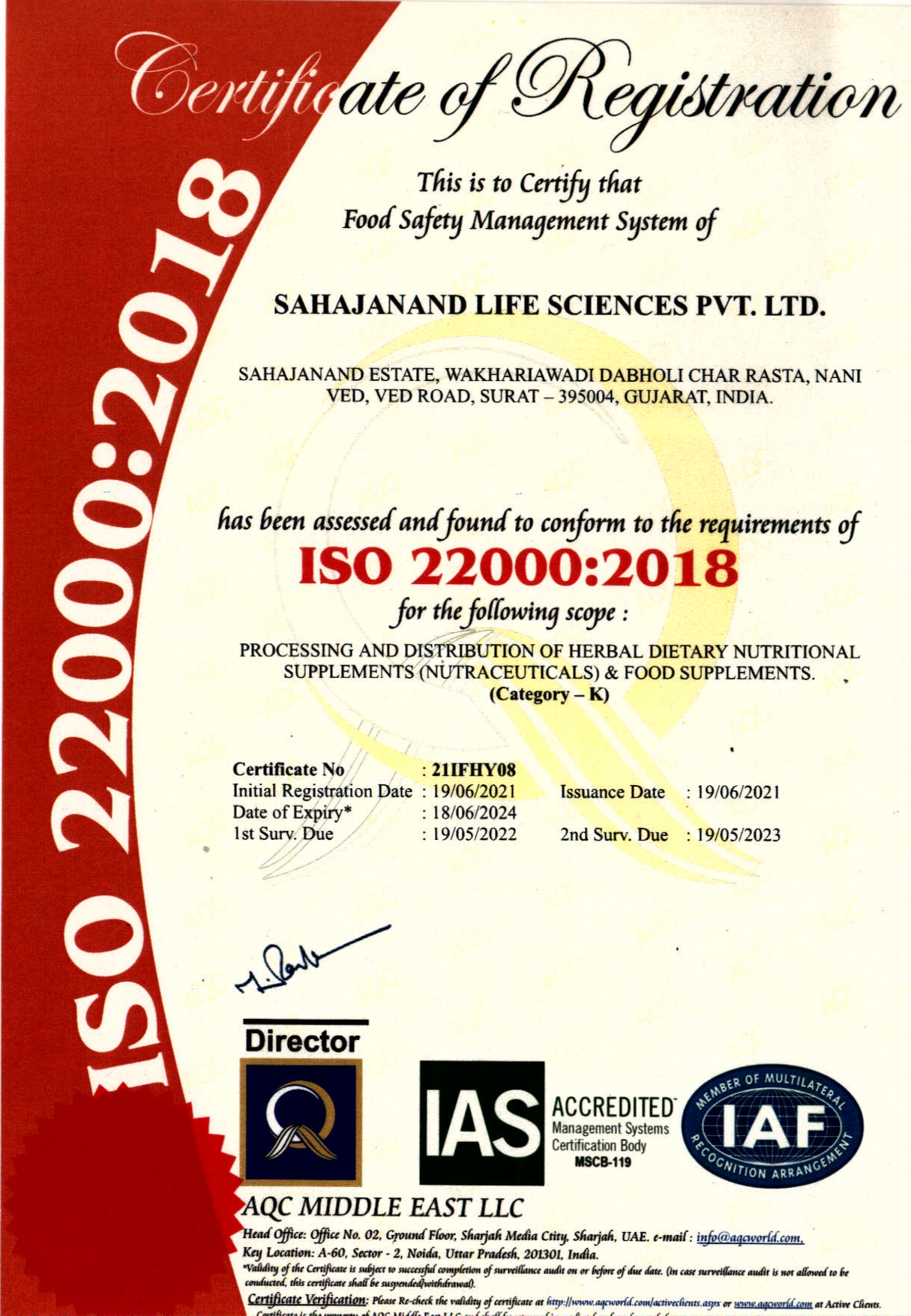

The 'State of the Art' manufacturing units of Sahajanand Life Sciences is cGMP (Current Good Manufacturing Practices) approved and ISO 9001:2015 and ISO 22000:2005 certified. We are the pioneer in using standardized herbal extracts to manufacture Ayurvedic medicine since 2001. We have a product range of over 35 patented Ayurvedic proprietary medicines. Our analytical laboratories also use equipment that adheres to cGMP and various pharmacopoeial standards.

The manufacturing process begins with the careful selection of raw materials that are processed under foolproof hygienic conditions. All the processes are regularly validated, calibrated and upgraded as and when necessary. Our quality control is a rigorous, painstaking process by itself, followed religiously for every product. More than 50 quality tests conducted to confirm the safety and efficacy of products. These complete quality management approach ensure the batch to batch consistency.

Our State-of- the- art manufacturing facility is equipped with fully automated modern machineries and equipment. We can manufacture medicines in capsules, granules, oils, syrups and semisolid dosage forms. The production processes take place under the watchful eyes of pharmacists, talented physicians, and health scientists along with expert technologists. Production and manufacturing facilities are fully geared for the mass production of Ayurvedic medicines in strict adherence to cGMP regulations. We have incorporated modern technology for mass production focusing on the traditional approach of Ayureveda, and made a synthesis of tradition and modernity. The Company's manufacturing operations are mostly mechanised and hence speedy, hygiene and accurate.